An explanation of flour ash, how it’s determined and what it means to millers and bakers.

By: Harold Ward, Technical Services

Credit: Bay State Milling

Flour ash. In the Milling Industry, it seems like we live and die by that number. Think about it, a number that is usually right around one half of one percent in, say, a typical bread flour has such a huge impact on what we do every day. It is a mainstay of flour specifications, whether they are defined by the miller, or the baker. Why do you suppose that is, and, is it as it should be?

Anyone that’s had the pleasure, or displeasure, depending on your perspective, of sitting through one of my talks on wheat and flour can tell you that this is one of my soapbox issues. So, here we go.

What exactly is flour ash?

Very basically flour ash is mineral content. In flour ash determination, we burn off a sample of flour and what is left after burning, the ash, is expressed as a percentage of the original sample weight. Let’s say, for example, 0.53% ash in a typical bread flour. The ash consists of minerals that were in the flour, as they do not combust. This is worth repeating, flour ash is mineral content.

Very basically flour ash is mineral content. In flour ash determination, we burn off a sample of flour and what is left after burning, the ash, is expressed as a percentage of the original sample weight. Let’s say, for example, 0.53% ash in a typical bread flour. The ash consists of minerals that were in the flour, as they do not combust. This is worth repeating, flour ash is mineral content.

Why do we measure flour ash?

To help make it clear why the miller measures flour ash, let me explain a little about the wheat kernel itself.

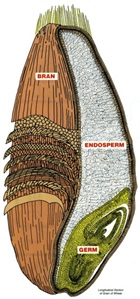

A wheat kernel has three major parts — bran, germ, and endosperm. The bran is the protective outer coating of the wheat kernel. The germ is the reproductive portion of the kernel from which a sprout would emerge if allowed to germinate. The endosperm is predominantly starch and is the energy supply for the growing wheat plant if the kernel sprouts. The endosperm is also the portion of the wheat kernel from which refined (white) flour comes.

In milling, a primary goal is to separate the three parts of the wheat kernel from one another as completely as possible. In general, the bran and germ have a higher mineral content than does the endosperm. Because of the difference in mineral content, the miller will use the ash content of the flour as a gauge of how well he is doing in achieving his goal of separating the bran and germ from the endosperm.

So what’s the problem?

Good question. The relationship of flour ash content to how well the miller has done in separating the bran and germ from the endosperm does not always hold true. It is directly impacted by how the growing wheat plant deposits minerals it has taken up from the soil into the wheat kernel. In some instances, the big differences in mineral content between the bran and germ portions and the endosperm may not be so big. Also, under the right conditions, a wheat plant may take up more minerals from the soil than typical, increasing the overall ash content of the wheat kernel. When either of these is the case, a miller may produce flour with higher ash content even though he has done a good job in making those separations. In essence the miller ends up with flour that has higher ash content but does not have unusually high levels of bran. The flipside of that is if either of those scenarios is the case and the Miller does what is required to achieve a lower flour ash value, he may well be removing more of the wheat kernel from the flour in the milling process that he normally would, changing the overall characteristics of the flour.

Now, here’s a big piece of information that will pull the story together. The mineral content of the flour does not have a negative impact on the flours baking characteristics. Yes, you read that right, flour ash content is not a guide to a flour’s baking quality. It is essentially neutral in that regard.

What!?! The ash content of flour doesn’t impact baking characteristics?? That can’t be true. We’ve been measuring flour ash since, well, forever! Well then, what does have a negative impact on baking characteristics? Bran content. Bran doesn’t bring anything positive to the party with regard to structure building. In fact, it tends to dilute and weigh down that structure and compete with other flour components for water.

Something to think about.

Ok, so ash content doesn’t have an impact on the baking quality of flour, but bran content does. And, you can have flour that is high in ash, but not high in bran. Maybe it’s time to start measuring and specifying something that actually has an impact on baking quality. Let me see…how about bran content? Makes perfect sense, right? Bran is the culprit. It’s the thing that hurts baking quality, so why not measure it instead of wasting time and energy on measuring and being constrained by something that really doesn’t cause problems.

Like I said earlier, we’ve been specifying and measuring ash content forever and it’s easy to get caught in the “we’ve always done it this way” trap. Just because we’ve always done it this way, doesn’t mean it’s the best way. We can change it, but it’s going to require a paradigm shift in the milling and baking industries.

Don’t just take my word for it. Check it out for yourself. Do some research. Give it some thought. Talk amongst yourselves. It only takes one nudge to get the ball rolling.